Food Grade Material

We adopt pure food grade material for our ceramic elements and atomized aerosols which have all passed strict industry safety certification

Defining the Future of Cannabis Vaping

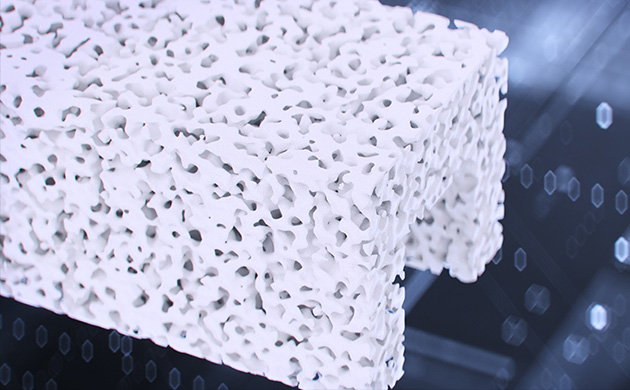

Our most advanced technology, which spent more than 800 days in R&D, represents revolutionary ceramic heater design. Adopting a ceramic core with ultra-high sintering temperature at 1,200 degrees, it evenly distributes 100 million micropores across the cannabis oil supply area, resulting in 2.4 times more capacity and a 35-percent increase in vape juice transfer speed.

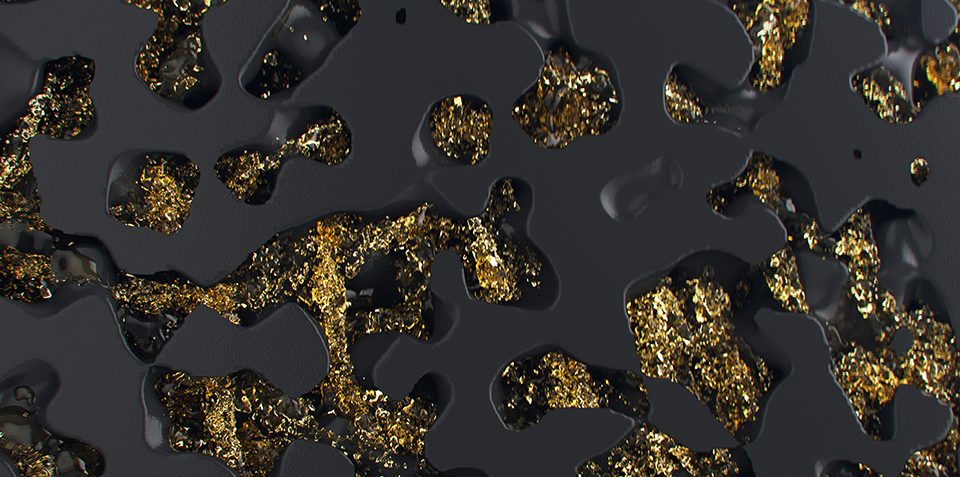

MAXCORE PUREXCORE ceramic elements and atomized aerosols are all made with food grade, heavy metal free materials strictly conformed to regulatory requirements.

The shape and size of ceramic heating element have been optimized to improve the atomization efficiency. As a result, It saves more than 20% battery consumption.

By improving the micro-pore structure and heating track design, MAXCORE PUREXCORE ensures 30% higher oil transfer velocity and full vaporization of viscosity, achieving great taste.

With MAXCORE PUREXCORE inside , the vaporizer can achieve bigger vapor amount from the first puff to last. The TPM can be 7 or higher than the industry average rate.

MAXCORE PUREXCORE can quickly vaporize the viscosity in 0.1 second. Furthermore, the flavor won’t decrease even after repeated use for 7 times according to our experiment results.

MAXCORE T10

Ceramic Heating Technology

– COTTON FREE Ceramic Innovation

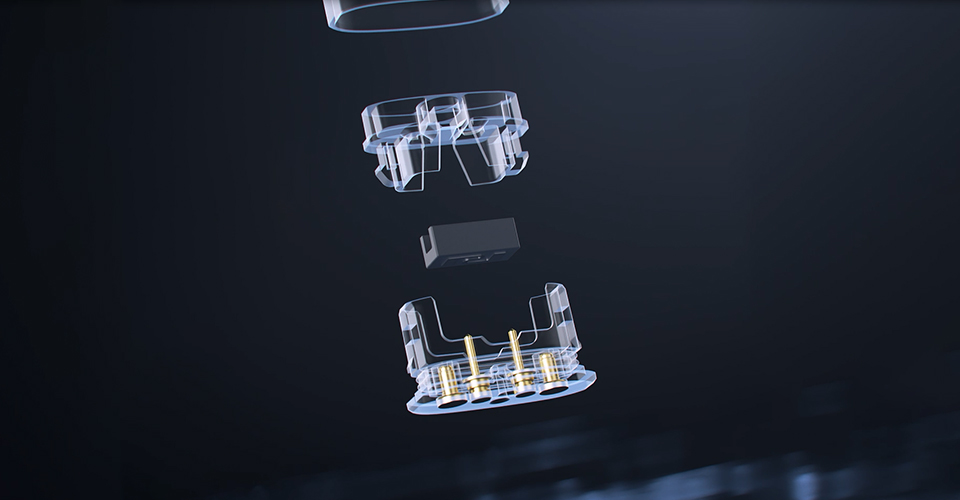

MAXCORE T10 is the first atomization technology with unique patented of Non-cotton ceramic, officially launched by MAXCORE. As an innovator of the" embedded in hollow cylinder " ceramic core, T10 adopts very special new food-grade ceramic material to greatly optimized porosity to make sure the excellent performance in guiding and locking oil.

The heating wire with high-strength nickel-chromium alloy material to improve the atomization efficiency and taste experience.

MAXCORE T10 ceramic elements and atomized aerosols are all made with food grade, heavy metal free materials strictly conformed to regulatory requirements. safety certification.

MAXCORE T10 reserves true flavor of your oil that’s closest to flower and ensures strong hit by perfectly balancing each elements including ceramic thermal conductivity, micropores structure, wire structure, etc. In a word, MAXCORE T10 can handle all CBD and THC oil of any viscosity well.

MAXCORE attaches great importance to patent development and protection, MAXCORE T10 attaches great importance to patent development and protection. Maxcore ’s mother company FirstUnion Group now owns more than 1490 patents worldwide, covering a number of fields including ceramic conductors and electronic atomizers.

MAXCORE T10 has uniform distribution of micropores which increases capillary action by 30% and soaks the oil properly, together with a well engineered cartridge structure, leakage is prevented. It also prevents overheated coil and overcooked juice.

PUREXCORE can quickly vaporize the viscosity in 0.1 second. Furthermore, the flavor won’t decrease even after repeated use for 7 times according to our experiment results.

Engineered to preserve oil’s authentic flavor, the specially for mulated ceramic core fully vaporizes a variety of viscosities to deliver maximum potency without burning, overheating, or waste. Ceramic heating elements including ceramic core porosity, ceramic formula, oil intake hole size, and resistance are customizable.

Defining the future of Cannabis Vaping

Our most advanced technology, which spent m ore than 800 days in R&D, represents revolutionary ceramic heater design. Adopting a ceramic core with ultra-high sintering temperature at 1,200 degrees, it evenly distributes 100 million micropores across the cannabis oil supply area, resulting in 2.4 times more capacity and a 35-percent increase in vape juice transfer

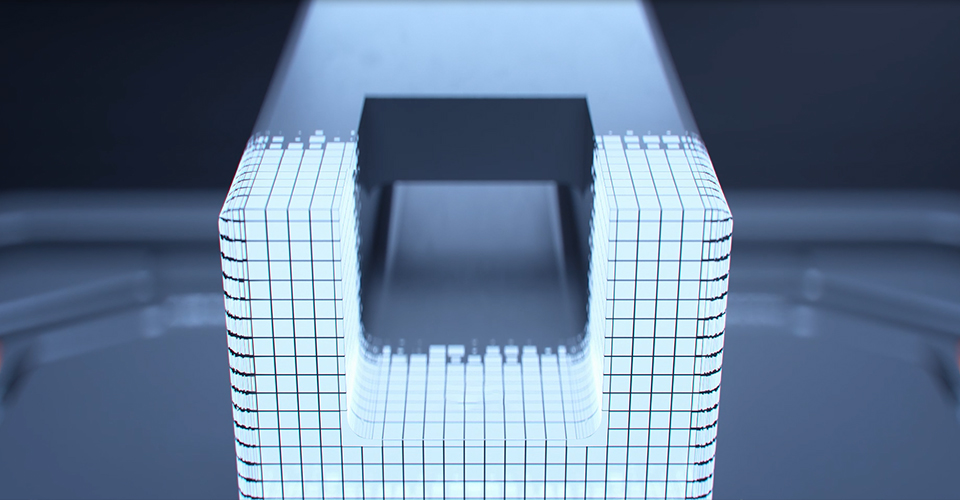

Ceramic Heating Technology – A New Level of Cannabis Vaping

Engineered to preserve cannabis oil’s authentic flavor, MAXCORE W19 stays true to the oil. Additionally, it goes well with all oil viscosities.Ceramic heating elements including ceramic core porosity, ceramic formula, oil intake hole size, and resistance are customizable.